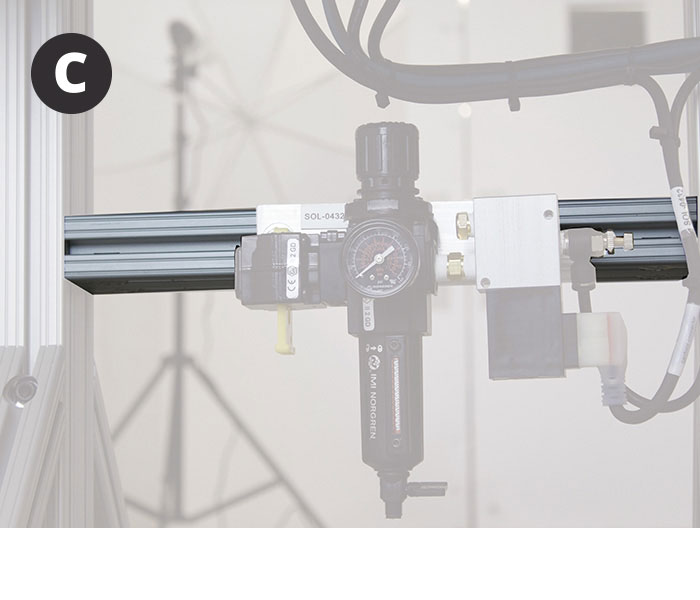

mvTower was developed for the customer who has limited resources (time/staff) to design and manufacture mechanical support structures for their machine vision applications. mvTower provides a stable, yet flexible mounting platform for cameras, lighting equipment, backdrops and other machine vision system devices. For applications that need an “air blow-off” rejection method, the mvTower can easily accommodate air nozzles, solenoids and a filter/regulator to connect and control plant air.

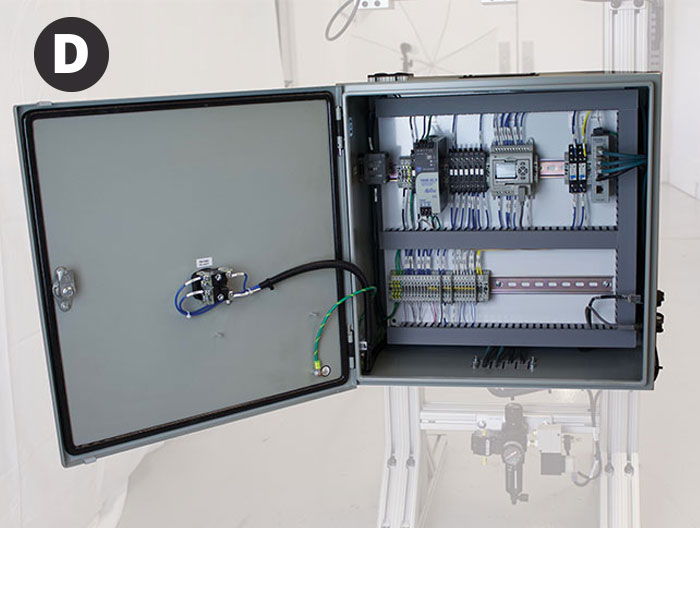

Only wish to do camera configuration and PLC programming? No problem! We can assemble, wire and test an electrical control panel for you (with UL508a certification, if needed) and interconnect the cables from cameras, lights and other devices to the control panel.

Review our “Components and Options” section, then call us for an estimate of cost and availability. You will find mvTower is a practical and economical solution for your machine vision applications.

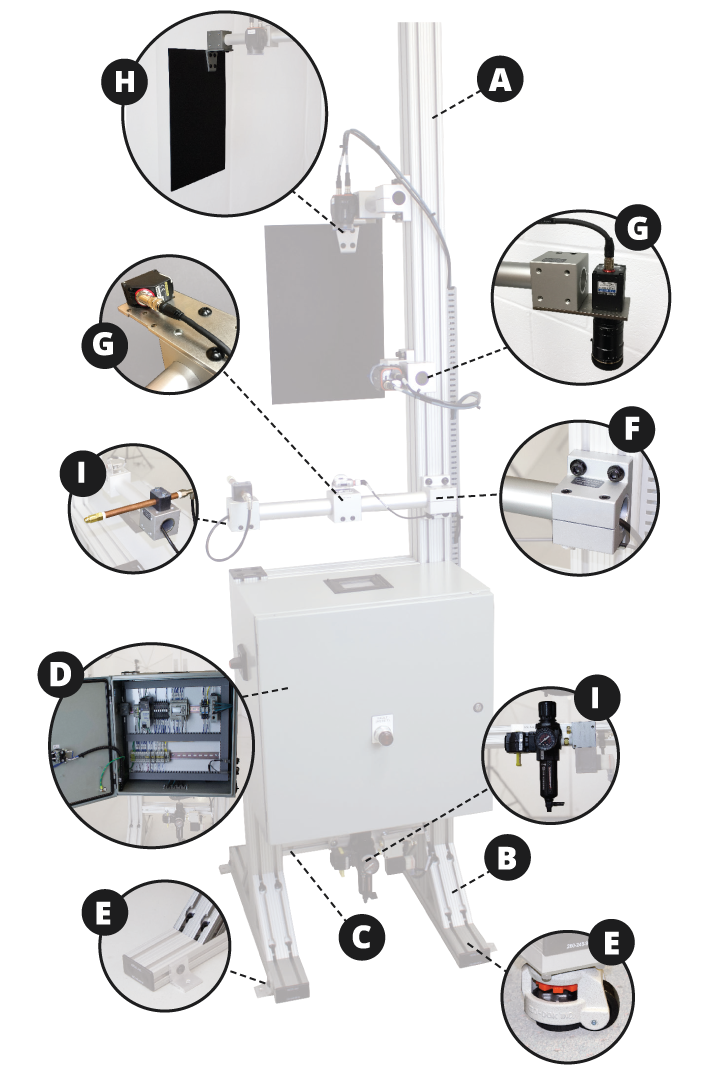

STANDARD: 72” High with Plastic End Cap

OPTIONAL: Can Be Taller For Elevated Conveyors

STANDARD: 36” High Leg with Plastic End Cap

OPTIONAL: Can Be Taller For Second Tower or Elevated Conveyors

STANDARD: Enclosure Width minus 6”

STANDARD:

- 20” High X 20” Wide X 10” Deep

OPTIONAL:

- Custom Size and/or Color

- NEMA 4, Mild Steel Painted Gray

- NEMA 4X Stainless Steel (Type 304 or 316)

- Cutouts: Front, Sides and/or Bottom (Provide Drawing & Details)

- Assemble, Wire and Test at Our Plant

- UL508a Label for Our Assembled and Wired Enclosures

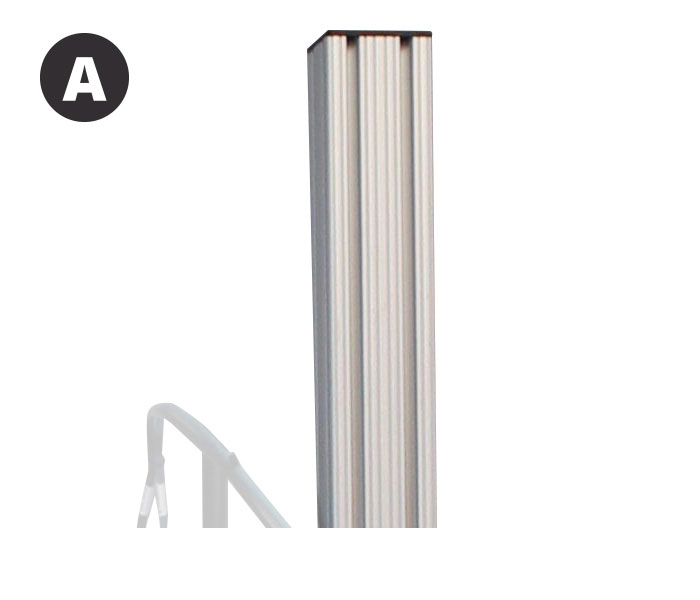

STANDARD:

- (2) 26” Deep Bases with Gussets

- (4) 90 Degree Mounting Tabs (*)

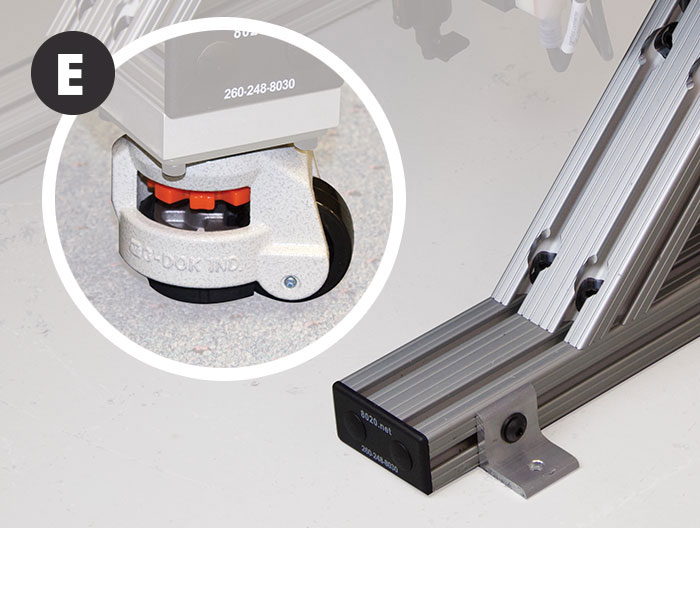

OPTIONAL:

- (2) X” Deep Bases with Gussets

- (4) Casters (Lockable and Height Adjustable)

- (4) Bolt-Down Adjustable Leveling Feet (*)

*Floor Fastening Hardware by Customer

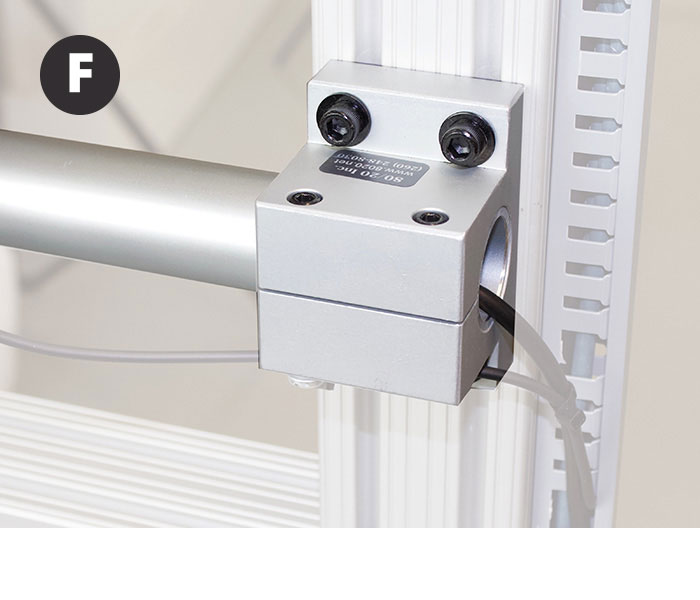

(26” Long Tube, Stanchion Base and Device Mount Stanchion Block)

Specify Required Quantity of Assemblies

Device Mount Block Has (4) Pre-Drilled 1/4-20 Holes For Attaching Item G. Additional Device Mount Stanchion Blocks Available

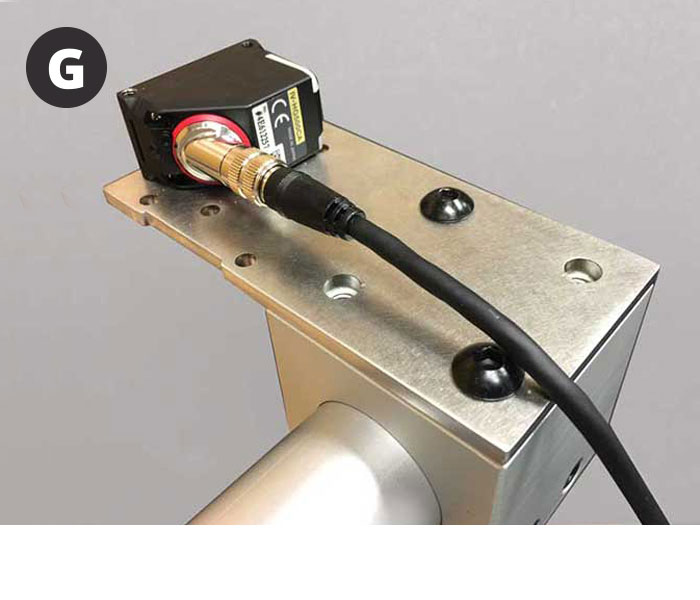

STANDARD:

- Pre-Drilled To Match Stanchion Block

- Includes (2) Screws to Attach Bracket to Stanchion Block

- Customer to Provide Holes at Blank End of Device Mount Bracket

OPTIONAL:

- Holes for Mounting Device to Bracket

- Provide Drawing of Pattern and Size/Tap Details

STANDARD:

- 18” High x 12” Wide, Black Mat Finish

- Includes Stanchion Device Block and L-Bracket

OPTIONAL:

- Custom Dimensions, Colors, Finishes

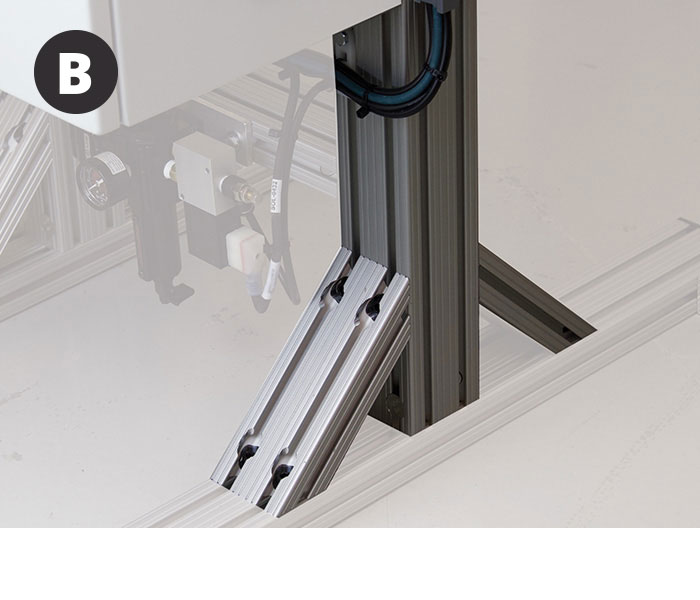

STANDARD:

- Air Solenoid Valve, 120 VAC Coil

- Air Filter/Pressure Regulator (for 80 to 120 PSI Plant Air)

- Safety LOTO Air Dump Valve

- Air Blow-Off Nozzle (Mounts To Device Mount Stanchion Block)

We can design and manufacture brackets for your cameras, lights, sensors and other devices. These brackets (Item G) attach to a Device Mount Stanchion Block (photo shows bracket for a Keyence Multi-Spectrum Light Ring and bracket for a Keyence Machine Vision Camera).

mvTower is an excellent building block for other applications too! Its unique architechture can be custom designed and manufactured to fit your requirements. We can provide you with technical services to design and fabricate complete machine vision system solutions for integration into a new or existing manufacturing line. Our services can also include selection and integration of in-line rejection equipment. Our objective is to provide you with a simple and reliable system that meets your technical requirements and satisfies your financial ROI goals!

Learn More